Engineering

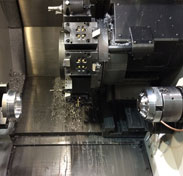

We are able to take your conceptual idea to a manufacturing process using the greatest tooling, and Cad/cam systems.

Read More

We at Steeda Manufacturing produce parts for industry leaders such as Steeda Autosports, Roush, XV Motorsports and Florida Highway Patrol, Ford, And Ford Racing just to name a few. We use the latest in Cad/Cam software to engineer and program our Cnc machine centers. Our Cad/Cam department has the capability to use and take a wide variety of file formats. We manufacture parts to OEM standards for some of our customers. We are able to do short run to large production quantities. Quality, On time delivery, and competitive pricing is our benchmark. We invite you to contact us to learn more about our service and capabilities, and also to be able to quote your machined part requirement.

Learn More View Our ServicesCustomer ideals achieved in a fast pace thus bringing that quality to you.

Learn More

Time to bring your idea to reality. Speed not only matters for the races

themselves, but also for our parts. Our in house prototyping capabilities allow

us to bring parts to reality with speed and accuracy. From concept to prototype,

we were able to bring our watts link, a suspension assembly with over 150

pieces, to life in 2 weeks for an NMRA event in Bradenton, Florida. Sometimes

our customers need their products before a production run. Our customer was

holding an open Track Event at the famed Sebring International Raceway for the

world debut of their Steeda GT500.

Not wanting to rest on our laurels, the Steeda Engineering Team took the GT500

to the "Ultimate Level" by using our CAD/CAM engineering modeling

intelligence, rapid design, and in-house manufacturing capabilities to deliver a

completed vehicle worthy of the name: The Steeda GT500. With powerful engine

upgrades and the most extensive suspension upgrades available. Included with

this upgrade is the all new and patented Coil over Suspension System, derived

from over one year of research and development that greatly enhances aggressive

performance driving without detracting from ride quality. Performance

modifications Steeda Engineering & Manufacturing designed for the car

All parts manufactured for Steeda Autosports are track tested for proven

performance. We currently have access to 3 premier road circuits and 3 drag

strips within 3 hours. Our custom 40' enclosed trailer makes transport to

and from the track a breeze. Our new facility will have an on-site test track

and drag strip within 15 minutes. Dario Orlando puts the Steeda Autosports Focus

ZX3 through its paces on his way to a second place finish during SCCA action at

Moroso Motorsports Park, Jupiter, Florida.

Fresh from their outstanding showing at the famed Sebring International Raceway,

Steeda President Dario Orlando and Racing Chief Engineer, Steve Chichisola

continued their very successful development process on the Steeda Focus ZX3.

This time, Moroso Motorsports Park in Jupiter Farms was the scene of the action

as the SCCA Florida Region hosted the Double South Atlantic Road Racing

Championship races. Dario Orlando qualified the Focus third in a field of 60

cars the first day. Dario stated, "We are getting the suspension dialed in

as we test and continue to develop new parts for our customers".

Encouraged by the progress of the Focus, Orlando explained, "We plan to

continue upgrading our ZX3 all season long as the development process continues.

The Focus is an exciting car both on the race track and on the street and we

look forward to engineering and developing more and more competition proven

Steeda Focus performance parts."

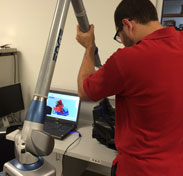

Our design team is the best in the industry, bringing the most innovative and

cutting edge designs to the market in the shortest time possible. In house

engineers use the latest 3D solid modeling CAD software (SolidWorks 2012) for

nearly all design and simulated testing. 3D models and assemblies are created

then ran through appropriate simulation programs (FEA, CFD, Fatigue) to validate

effectiveness and efficiency.

Following digital optimization, designs are typically Rapid Prototyped with our

in house Rapid Prototyping machine. A 3DSystems machine is used in our office to

build exact replicas of 3D CAD designs. The parts, or even assemblies, can be

made in one print with all parts holding tight tolerances that can be used to

further validate aesthetics, fitment, and even function. This saves everyone

time and money by not having to have low-volume parts run on their respective

high-volume manufacturing machines.

Final physical prototypes are then manufactured in-house for all testing

purposes. Short turnaround time, a dedicated staff, and prototype-only machines

help to get parts in testing as quickly as possible.

What made the difference was Simple: Most sway bars that are available today are

made from a solid round bar whose ends are smashed flat and drilled for mounting

holes. The drastic change to the cold formed material creates many small

microscopic stress fractures. Experienced metallurgists will tell you that

whenever you do that, you effectively destroy the structural integrity of the

material thereby creating a potentially weak spot or a potential future point of

failure.

As members of the SEMA Technology Transfer Program, we were supplied in advance

with engineering data directly from Ford, so the design phase began. Yet between

design changes from the factory (some parts we designed had to be re-engineered

to suit), delays in receiving our first production car and, the occasional snafu

with suppliers, Team Steeda persevered.

The result of these efforts is quite dramatic. The thirty of the 100+ parts our

customer's wanted for the '05 were being inventoried at our customer's

distribution centers. So we met our customer's goal of having these parts

ready by the time dealers across the country have taken delivery of their cars.

In fact, we've pretty much beat the "after" right out of the

aftermarket.

While many vendors were still showing 'renderings' of their intended

designs, or had un-drivable 'concept cars' on display, Ford Customers

were able to see, and even experience, the actual products on an actual

production car. At Steeda Engineering & Manufacturing, "Speed Matters"

- always on the track and in cases like this, in the marketplace as well.

Steeda offers a collection of Q cars ranging from 350 horsepower to 650 horsepower with a host of different suspension options. These Q cars can be purchased directly from your local Ford dealer. Not only are the cars fast, but they are also put together with speed and precision. Our shop is capable of building each of these cars, with 40 plus new parts, in a matter of days.

All of our parts are made at the plant and in the USA. Contact us today to find out we can help you.

Yes, we do and we can help get that part you need. Check out our website at steeda.com

Yes, we can. Just contact us and let us help find that perfect part and installation you are seeking.